Additive Upgrade Kit for Industrial Robots or Gantry Systems

(Developer Package) – Includes PE320 Extruder, Control Console and Air Flow (Pellet Delivery System)

The Additive Upgrade Kit is designed as a value solution to enter large format pellet extrusion, the package when added to a robot or gantry/CNC system gives you full additive capabilities.

The low-cost solution is specifically for developers looking to add new capabilities to their current hardware.

Our lightweight extruder can be added to almost any industrial robots such as Kuka, ABB, Fanuc, and many gantry systems with a payload over 20kg, coupled with a material flow of 17kg per/h it really is best in class.

The PE320 is capable of handling many different polymers whether that’s PLA for low-cost prototypes, ABS for trim tools and fixtures or PEI for industrial applications such as moulds/Autoclave Moulds.

The developer package is suited to those that already have the in-house technical ability to retro fit the solution whether you are a manufacturing institute, university, or a specialist engineering organisation.

Why pay for a full additive solution if you already have the hardware in situ that can be reborn for an large additive 3D printing system?

The Additive Upgrade Kit is a limited run to enable organisations to enter large scale additive without the cost barrier to entry.

**Before purchasing this solution please contact our sales team for approval to purchase this solution.

What’s in the box….

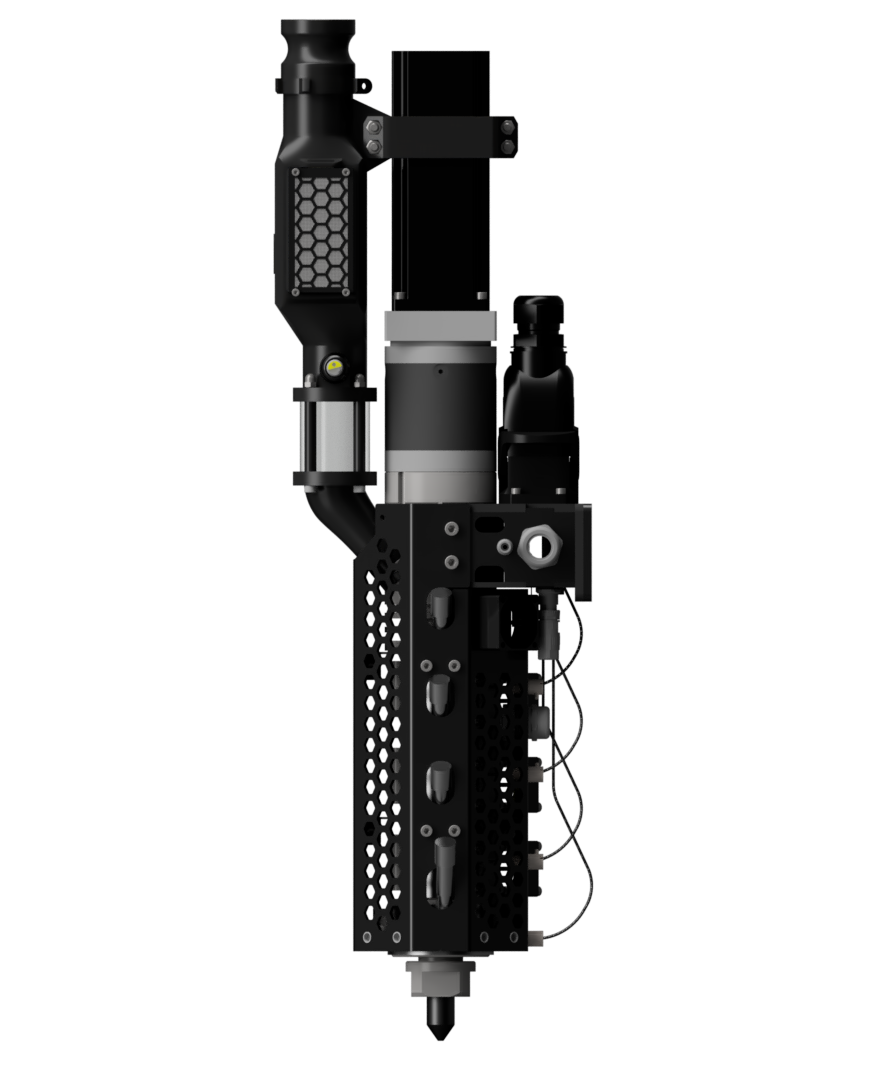

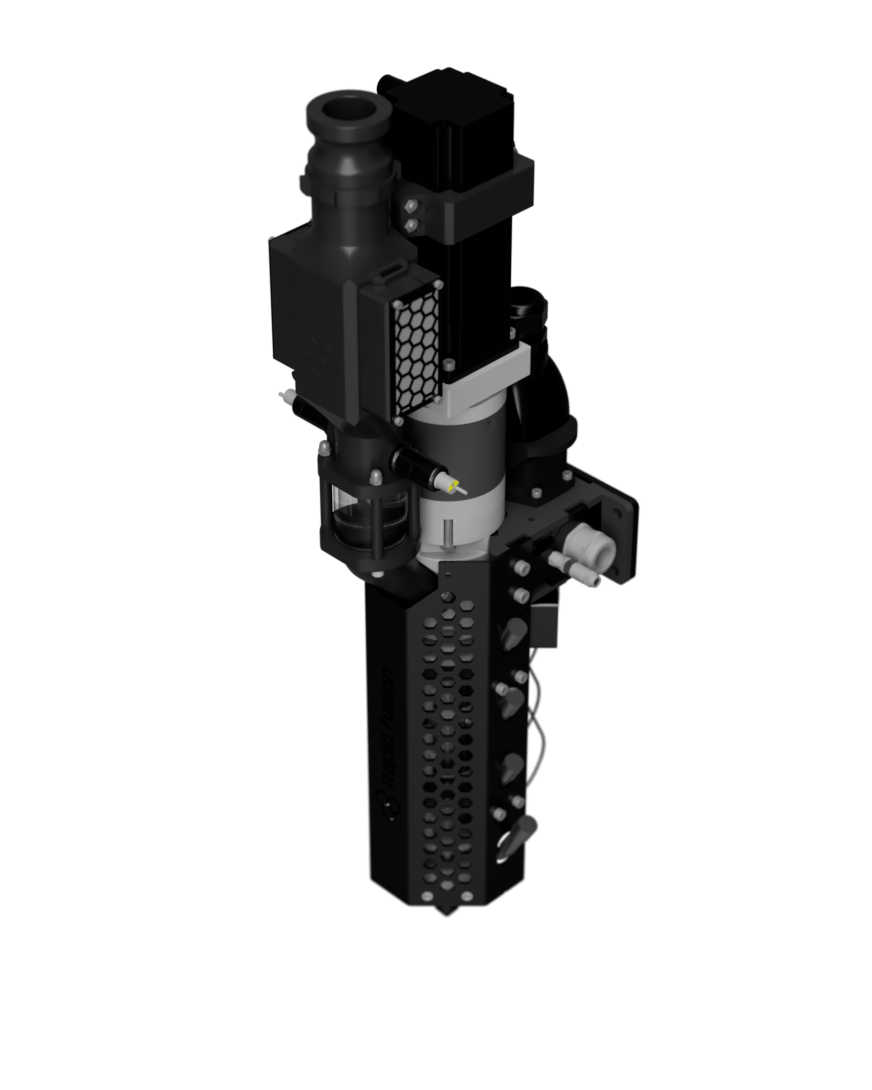

PE320 Extruder

The Rapid Fusion PE-320 Pellet Extruder is a versatile and powerful tool designed for industrial - grade 3D printing. It offers high -performance capabilities and can be seamlessly integrated into CNC machines and robots unlocking a new dimension of possibilities. With its advanced features and precise temperature control this extruder allows for efficient extrusion of a wide range of materials, including abrasive ones like carbon fibre. It combines power, precision, and versatility making it an excellent choice for upgrading and expanding capabilities on robot or CNC setup

Epicurus Control Panel

Introducing the Rapid Fusion Control Console, a powerful open-source control solution designed to maximize the potential of additive manufacturing. With seamless integration with the Rapid Fusion PE 320 and compatibility with other systems, this control console offers robust connectivity, precise temperature control, customizable IO capabilities, and enhanced safety compliance. Experience real-time control of the servo drive when connected to a robot for optimal printing results, unleash the power of 3D printing with ease

Rapid Fusion Air Plus

Efficient Pellet Feeding System for Uninterrupted Printing:

Introducing the Rapid Fusion Air Plus, a powerful pellet feeding system designed to ensure a consistent supply of material to your pellet extruder. With its innovative features and reliable performance this system keeps your3D printing process running smoothly preventing material shortage and enhancing overall efficiency.

Enhance Your 3D Printing Workflow:

The RAPID Fusion Air Plus offers seamless integration with our control panel, providing a comprehensive solution for enhanced 3D printing performance. Experience uninterrupted printing with a reliable and efficient pellet feeding system.

Optional Extras

Accessories

Atlas Modular Heated Bed 1mx1m

40-300 Litre Pellet Dryer

Material Hopper

Software

AI Build Sync

Adaxis Adaone

Services

Installation

Support