Enhancing Print Quality with Advanced Retraction Algorithms on the PE320 Pellet Extruder

At Rapid Fusion, we are constantly pushing the boundaries of additive manufacturing to deliver superior performance and unparalleled quality. One of our recent milestones is the development of an advanced retraction algorithm for our PE320 Pellet Extruder, in collaboration with our software partner, Adaxis.

Why Retraction Matters

In 3D printing, retraction is a critical function that helps in reducing oozing and stringing, ensuring cleaner transitions between print paths. When the extruder moves from one point to another without depositing material, retraction pulls back the material to prevent excess material from leaking out. This process is especially crucial for complex geometries and detailed prints where precision is paramount.

The Challenge

Traditional retraction mechanisms often fall short in maintaining consistent print quality, particularly when dealing with pellet extrusion systems. The dynamics of pellet extruders, like the PE320, are different from those of filament-based extruders, requiring a more nuanced approach to manage retraction effectively.

Our Solution: A Tailored Retraction Algorithm

To address these challenges, our team at Rapid Fusion, in collaboration with Adaxis, has developed a sophisticated retraction algorithm tailored specifically for the PE320 Pellet Extruder. Here’s how our solution stands out:

- Dynamic Retraction Control: Our algorithm intelligently adjusts the retraction distance and speed based on the specific requirements of the print job. This ensures optimal material flow and prevents issues like oozing and stringing, even with complex designs.

- Real-Time Adjustments: Leveraging the integration with Adaxis’ ADAONE software, the algorithm makes real-time adjustments to the extruder’s behaviour. This dynamic control is crucial for maintaining high-quality prints, especially when dealing with varying speeds and directions.

- Minimise Material Waste: By precisely controlling the retraction process, we significantly reduce material waste. This not only leads to cost savings but also supports our commitment to sustainable manufacturing practices.

- Enhanced Print Speed and Quality: The improved retraction capabilities enable faster print speeds without compromising on quality. This is particularly beneficial for large-scale prints where time efficiency is critical.

Real-World Impact

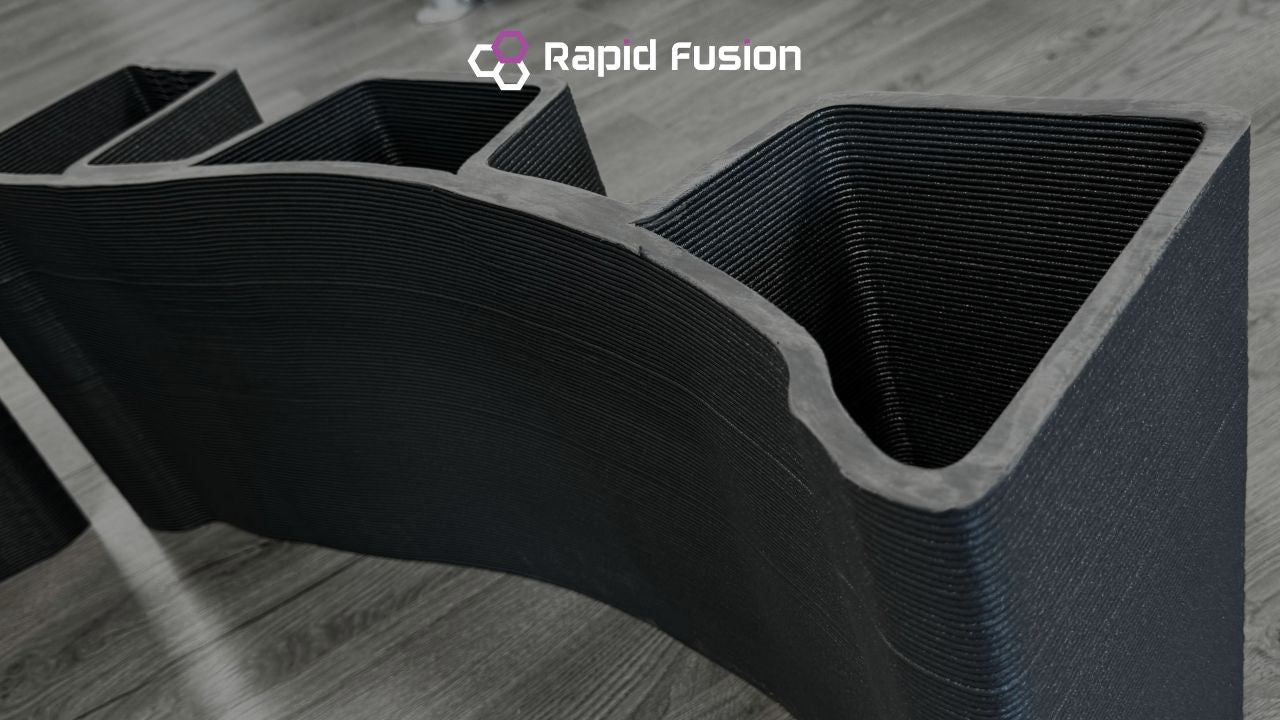

Our advanced retraction algorithm has already demonstrated impressive results in various applications. Notably, it has enabled the serial production of products. In the video enclosed, you can see two moulds being printed simultaneously with zero stringing and oozing. This ensures no artefacts are travelling up the print, maintaining the integrity and precision of the final product.

Conclusion

The development of this advanced retraction algorithm marks a significant step forward in our journey to revolutionise additive manufacturing. By addressing the unique challenges of pellet extrusion, we are able to provide our customers with cutting-edge solutions that enhance both efficiency and print quality.

We are proud of our partnership with Adaxis and the remarkable synergy between their ADAONE software and our PE320 Pellet Extruder. Together, we are setting new standards in the industry and paving the way for more innovative and sustainable manufacturing practices.

Stay tuned for more updates and advancements as we continue to push the limits of what’s possible in 3D printing!